Textile and Apparel Waste: Classifications, Elements, Origins

Wasting in the Textile and Clothes Game

Stuff that's useless? That's waste, mate. And it takes a big toll on the money-making ratio in the textile and fashion biz. It'll clobber your bottom line, wreaking havoc on your efforts, investments, and time. Instead of boosting profits, it shrinks 'em. But here's the good news: slashing waste could save bunches of dough in the textile and apparel production world. This piece dives into the nitty-gritty of Waste in the Textile and Clothing Sector: Forms of Waste, Types of Waste, and Reasons for the Waste Pile-Up in the Textile and Fashion Biz.

These days, the textile and clothing market is fierce. Consumers keen on quality expect low prices. To survive and ride the waves of competition, manufacturers must trim costs in innovative ways. Now, here's the tricky part when you're thinking of cutting costs-wastage is one of the biggest expenses. So let's delve further into the details of Waste in the Textile and Clothing Game: Forms of Waste, Categories of Waste, and the Who, What, Why behind the Waste in the Textile and Fashion World.

What exactly is Waste in the Textile and Clothes Biz?

Waste, or waste material, is essentially rubbish—the gash from the production process that's no good, no use. It's the difference between the amount going in (inputs) and the amount coming out (outputs), measured as a percentage. When a material goes through various production stages, some of it turns to waste due to various reasons.

Types of Waste in the Textile and Fashion Biz

Waste in the textile and fashion game can be broadly split into two: routine waste and blooper waste.

1. Routine Waste

This is waste that's unavoidable during normal production. It's part of the process, even under efficient, well-managed situations. This waste pops up due to factors such as:

- Imprecise measuring of materials.

- Discrepancies between the units purchased and used.

- Natural occurrences like evaporation, shrinkage, or cutting losses.

Since routine waste is an expected part of the operation, it gets folded into the overall production costs.

2. Blooper Waste

This is waste beyond the typical expected level of routine waste. It weasels its way in due to operational inefficiencies such as:

- Silly mistakes in handling materials or storage.

- Negligence in production processes.

- Subpar workmanship or excessive rework.

Unlike routine waste, blooper waste doesn't get added to production costs. Instead, it's treated as a separate loss. To squash recurrences, corrective measures are required. Distinctions boil down to predictability and control-routine waste is inevitable, while blooper waste points to operational inefficiencies.

Waste Categories in Textiles

The categories of waste generated in textiles are generally classified into four:

- Tough-to-Tackle Waste: This waste category is a pain. Sources of tough-to-tackle waste include persistent, treatment-resistant materials like non-biodegradable organic or inorganic materials containing color, metals, phenols, unhealthy organic compounds, pesticides, and phosphates.

- Risky or Unhealthy Waste: This waste category includes hazardous materials such as metals, chlorine-based solvents, non-biodegradable or volatile organic compounds. Many of these materials are often used for non-process applications like machine cleaning.

- High-Volume Waste: Large volumes of waste are a significant snag in the textile manufacturing process. Common high-volume waste types include:

- High volumes of wastewater.

- Washing water from preparation and continuous coloring processes and alkaline waste from propaedeutic processes.

- Batch dye waste with high salt, acid, or alkali content.

- Dispersible Waste: Waste generated during subsequent textile operations is highly dispersible. Typical sources include screen printing pastes, lint from preparation, coloring, and washing operations, foam from coating operations, solvents from machine cleaning, and still bottoms from solvent recovery processes.

The Root Causes of Wastage or Waste Production in Textile and Fashion

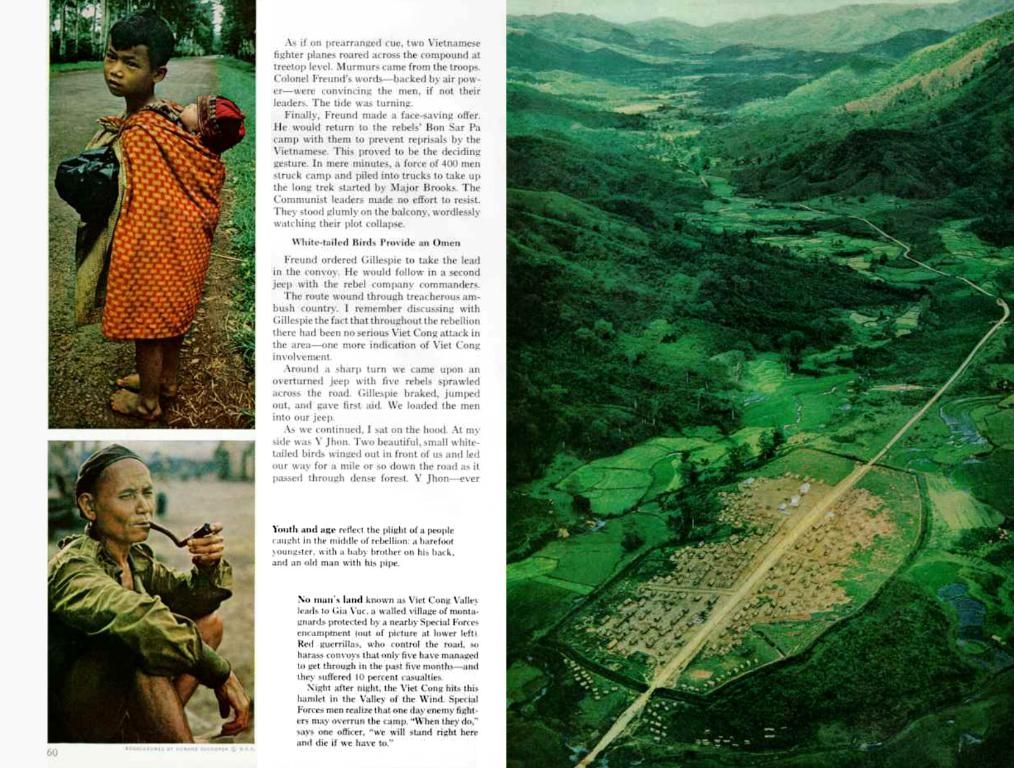

Waste or waste products in the textile and fashion game come in various forms:

- Leftover raw materials: Remaining input raw materials at the end of the production process in specific areas like yarn cones and creels for knitting, warping, etc.

- Scraps from production: These pop up during manufacturing processes like machine breakdown, cutting, shaping, or finishing, and can't be reused for production purposes. Examples include textile waste from fabric-cutting operations.

- Rejections: These are rejected production units that fail to meet product standards or buyer requirements due to defects or flaws, poor workmanship, etc. In the garment manufacturing realm, it's usually sold at discounted prices.

- Trial runs: In some processes, trial runs need to be carried out before venturing into bulk production to achieve desired processing conditions. This portion of the material can't be utilized further. For example, testing runs for printing, finishing, etc.

- Handling mishaps: These errors arise due to poor material handling during wet processing stages, where buttons and labels are lost during sewing operations due to carelessness, etc.

The Bottom Line

No textile or fashion company wants to produce waste. By improving handling during production processes, we can reduce waste. Textile raw materials and different methods and processes lead to higher waste percentages. Lack of awareness, flawed concepts, and a lack of standardization contribute to increasing waste in garment manufacturing. Standardization is crucial to control and minimize waste in apparel production. After conducting numerous studies and analyzing data, the average standard waste or waste percentage for each process, machine, material, or method must be finalized.

- You might dig: Various Forms of Waste in Spinning Mill Production***

- Waste Disposal Policy in the Garments Industry*

- Textile Effluent Characteristics and Waste Treatment Methods*

- Levels of Wastewater Treatment Processes in Textile Manufacturing*

Spread the News:

- In the textile and fashion industry, waste material, the unwanted output from the production process, is a significant concern due to its impact on costs and profits.

- Routine waste, unavoidable during normal production, emerges due to factors like imprecise material measurement, natural occurring losses, and discrepancies between purchased and used units.

- Blooper waste, on the other hand, is waste beyond the expected level of routine waste, occurring due to operational inefficiencies such as mistakes in handling materials, negligence in production processes, and subpar workmanship.

- The categories of waste generated in textiles are classified into four, including tough-to-tackle waste, risky or unhealthy waste, high-volume waste, and dispersible waste.

- Wastage in the textile and fashion industry stems from various sources, such as leftover raw materials, scraps from production, rejections, trial runs, and handling mishaps, which can be reduced by improving handling during production processes and standardization in garment manufacturing.